Rating of the best high-temperature thermal insulation for 2024

Materials designed to isolate heat sources from the environment are called high temperature materials. Resistance to high temperatures is a useful insulation property that is widely used in industry, construction and in everyday life. Due to the chemical composition of the substances from which the thermal insulation is made, it is able to withstand the effects of extreme temperatures.

The building materials market today offers a fairly wide selection of thermal insulation products that can withstand high temperatures. The temperature limits for the use of such protective equipment are in the range of up to 2000 degrees Celsius.

Places of use of high temperature insulation

Refractory insulation differs in composition and method of production, depending on the intended location and possibilities of its use. Properly selected material guarantees the safety of property and its full-scale use. Fire retardants reduce heat loss, protect adjacent materials from fire, and can serve as sound insulation.

- Fire-resistant insulation is used in the construction of walls and ceilings. These can be residential buildings or industrial facilities. From what the construction object is being built does not matter. It can be brick, concrete slabs, or wood. Mineral or basalt wool can be used here, which does not burn and does not absorb moisture. The form of the material can be any - plates, rolls or mats, depending on your wishes.

- For the protection of metal chimneys, pipelines of water, gas and combustible materials, it is used as thermal insulation from the external environment.

- Metallic foil with enhanced heat-reflecting property is used to insulate the chimneys of domestic heating stoves, fireplaces and baths. It is also used to fill the areas adjacent to the chimneys.

- Fireproof doors, gates, fireproof partitions use refractory material to fill voids. Fire-fighting means of protecting openings must comply with safety standards - be able to resist the penetration of fire and smoke.

- The material used for thermal insulation of engines of machines, installations that generate electricity, must prevent unnecessary heat consumption, heating of adjacent surfaces and have the property of sound insulation.

Parameters of fire resistant materials

The choice of thermal insulation is carried out according to certain parameters. Not every product is able to withstand the highest possible temperature, or serve as a sound insulator, or carry any kind of aesthetic load. The main parameters when choosing should be:

- Preparation method.It can be mineral wool or high-tech basalt material, or fiberglass.

- Density and, accordingly, specific gravity, which determines the ability to withstand the load on building structures.

- Thickness. It is regulated by the area of application and the desired result. For pipes, for example, thin felt or foil can be used, and for filling voids in refractory structures, thicker ones - mats or plates;

- Physical state and appearance.

Form and structure

Refractory materials are divided into several types depending on the physical state and shape of the product.

- Tiled - produced in the form of mats, they come in different sizes. Convenient for construction work.

- Liquid foaming. Dry after application to the desired area. They are used in the construction of ventilation, pipe insulation.

- Loose. Used as an admixture to other substances. Usually used for interior decoration, for example, underfloor heating.

- Wireframe. It is used in engineering insulation in the construction of large facilities.

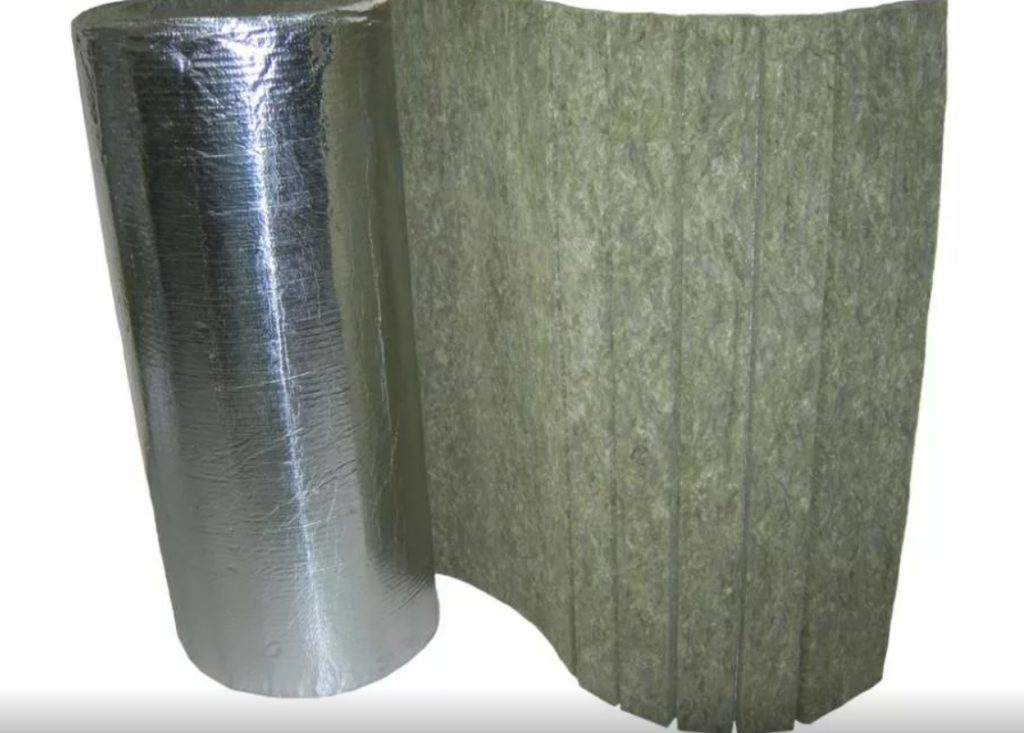

- Rolled. Convenient to use, allows you to wrap any design.

Types of non-combustible high-temperature insulating materials by manufacturing method

All types of high-temperature insulation differ from each other in the way of production and the composition of the raw materials. Below are the main high temperature thermal insulation products found in the construction markets. Both the proven ones and new high-tech ones are described.

- The oldest non-combustible material widely used in industry is rock wool. Produced from metallurgical waste and quartz sand. One of the cheapest. It can be produced in the form of plates and sheets. Less commonly, it is packed with cotton mass in bags and is used to fill voids in the construction of, for example, houses. For insulation of high temperatures, it is used only in combination with more heat-resistant products.

- Expanded clay, perlite and vermiculite are free-flowing granules; for thermal insulation they are used only in a mixture with other substances, for example, for installing underfloor heating in rooms.

- Fire-resistant foam is a product obtained by foaming polyurethane, in which fire retardants are added for fire protection.

- Velit - foamed concrete with a porous structure, which reduces its weight and density.

- Glass pore. This free-flowing composition is obtained by melting potassium or sodium glasses, followed by a sharp cooling of the composition. It is not used on its own, but only as part of mixtures where it is added as a means to increase fire resistance. It is used to make piece products that resist fire.

- Basalt thermal insulation material, made from molten basalt, is one of the safest to use, withstand high temperatures. Widespread due to its versatility. Can be used for indoor and outdoor use, and in high humidity conditions.

- Foam glass. It is obtained by sintering broken glass with coal, which is added for the gas formation reaction. Does not burn at all, almost does not conduct heat, withstands enormous temperatures. Most often used for thermal insulation of rooms with a wet technological process.

How to choose the right high temperature insulation material

When choosing thermal insulation, attention is paid not only to what the product is made of, but also to many other factors. During the purchase, first of all, you must carefully read the technical characteristics and pay attention to the fire safety certificate, where the NG (non-combustible) marking should be. All other options are not considered. Only after that, attention is paid to additional characteristics.

- Hygroscopicity and moisture resistance - especially important when working in humid climates;

- Good thermal insulation properties, which are determined by the thermal conductivity index;

- Good sound insulation;

- High density with low weight;

- Strength;

- Durability of use without loss of physical properties and its based purpose;

- The cost should preferably be low;

- Ease of use;

- Safety of use, products must not be toxic, with a rise in temperature or fire, the release of hazardous substances is not allowed;

- In some cases, it is good if the chosen option will provide comprehensive protection from both high temperatures and moisture, and also serve as a sound insulator.

Best High Temperature Insulation 2024

In the modern construction market, the choice of thermal retention insulation is quite wide. The buyer is presented with products of foreign and Russian manufacturers. Depending on your needs, you can easily find the option that will meet all the desired requirements. It is clear that the main property of such insulation is protection against high temperatures, however, their areas of application may vary. Some are used in industry, others - in the construction of baths, fireplaces, to protect pipelines, electrical systems.

Expanded vermiculite

A modern high-tech product that is widely used for the insulation of private houses. It is a granular coating that can withstand high temperatures and is not a medium for the development of microorganisms. Serves a long time. Does not lose its technical properties in the temperature range from minus 256 to plus 1100 degrees C. It is a good sound insulator.

- Does not harm humans due to its natural composition, it is produced by high-temperature firing of mica;

- Wide range of applications;

- Inexpensive, cost up to 1000 rubles per bag;

- Resistant to mechanical stress.

- Not resistant to moisture. Cannot be used in humid rooms, preferably in dry climates.

Foam glass P-600-450-150-1

Excellent thermal insulation for industrial facilities. It is produced by high-temperature action on glass with the addition of carbon, which gives the products a porous structure. Withstands high temperatures and has a long service life. These characteristics make it possible to use it to ensure fire safety in a wide variety of places under construction - for walls, basements, floors. It is not advisable to use it on the roof due to its heavy weight.

- Withstands high temperatures;

- When the heat threshold is exceeded, it melts without emitting toxic substances;

- Service life - 100 years;

- Easy to assemble and process.

- Large weight;

- High cost - up to 20,000 rubles per sq. M.

Calcium silicate thermal insulation boards Silka 250KM

They are widely used in the construction of furnaces. High performance properties at high temperatures keep this product among the best for many years. According to customer reviews, this is an excellent ratio of product quality and price. They are lightweight and durable, made in the form of slabs, which facilitates the construction process.

- Temperature limit - 1100 degrees Celsius;

- Non-toxic. Natural products are used for production;

- Solid and durable;

- Wear resistant.

- Not detected.

Basalt wool Technonikol Technoakkustik

Perfect for insulating floors and ceilings of buildings. Available in packs of 12 plates. Does not burn, when the maximum permissible temperature is exceeded, it begins to melt. The service life is up to 50 years. Does not transmit sound, which makes it indispensable in special rooms, engine rooms on ships, in industry. In production, heat-resistant qualities are often enhanced by adding metal waste to the composition.

- Versatility in application;

- Quality manufacturing;

- Low cost - from 1200 rubles per package of 12 pieces;

- Convenient shape for easy handling.

- Low resistance to moisture.

Pyrogels XT

New product based on airgel properties. Available in rolls. The thickness of the blade is 5 and 10 mm. It is widely used for insulating high and medium pressure pipelines, for insulating shields of electricity. A distinctive feature is flexibility, small thickness and lightness. The low weight does not place additional stress on pipe supports and other equipment. Compress well without damage. Easy to use, cut and bend. Not dusty. Withstands temperatures up to 650 degrees. The price starts from 1000 rubles per 1 sq. M.

- Ease;

- Strength, ability to easily withstand surface deformation;

- Moisture resistance, prevents corrosion;

- Can withstand dynamic loads.

- High price.

Mullite-silica felt MKRF-100

Available in rolls from 5 to 15 meters long. Withstands temperatures up to 1150 degrees. The thickness of the web is 20 cm. It is made of silica fibers by melting aluminum and silicon oxides in a furnace. To make the fiber soft and flexible, inorganic components are added to it. They are used as insulation of support for continuous furnaces, for insulation of arches, linings, heat-treatment furnaces, for elements of blast furnaces. For insulation of electrical installations, chimneys, steam lines, boiler rooms, door seals and in many more cases.

- Versatility of application;

- Flexibility and ease of use;

- Can be cut to any shape with scissors;

- It can be produced in ribbons, sheets, which expands its capabilities;

- Bonded to the surface with inorganic adhesive.

- Not detected.

High-temperature mats MVT-1200

They are a layer of mullite-silica wool and a layer of glass wool, quilted with each other. They provide heat protection and thermal insulation in a wide variety of industries for various mechanisms and structures. They are used as refractory covers and substrates for protection against metal splashes. They are used in the oil and construction industries, at thermal power plants, in boiler houses, in shipbuilding and metallurgy. Serve for electrical insulation of power lines. They reach a width of 400 mm, a temperature range from minus 60 to plus 1250 degrees.

- Wide range of applications;

- Ease of use;

- Strength;

- It stretches a little.

- Heavy. The weight of one mat is 7.5 kg.

Felt MKRF-200

Rolled in roll water, it has excellent flexibility, strength and fire resistance. Resistant to alkali and acid. Easy to use. Cutting is done with scissors or a knife. Fastened with inorganic glue or metal fittings. It accumulates almost no heat and has a low thermal conductivity. It begins to melt at a temperature of 1760 degrees. There is no need to install expansion joints, the material does not expand at all under the influence of heat. Wide application in industry and everyday life. Suitable also for heat insulation in stoves and fireplaces, for cable insulation.

- Indispensable as a high-temperature gasket;

- Easy to use;

- Withstands huge positive temperatures;

- Resistant to acids and alkalis, however, when exposed to high temperatures, it does not withstand aggressive concentrated acids;

- Good sound insulation properties;

- Flexible and durable.

- Not detected.

In the modern world, more and more attention is paid to thermal insulation materials. Not a single type of construction is complete without the use of thermal insulation. According to fire safety rules, the use of high-temperature insulation is necessary to protect objects from fire. A wrong choice, saving on one's own safety can lead to disastrous results from the loss of property to the loss of human lives. This is a case where selection mistakes can be very expensive.

new entries

Categories

Useful

Popular articles

-

Top rating of the best and inexpensive scooters up to 50 cubic meters in 2024

Views: 97661 -

Rating of the best materials for noise insulation for an apartment in 2024

Views: 95022 -

Rating of cheap analogues of expensive medicines for flu and colds for 2024

Views: 91751 -

The best men's running shoes in 2024

Views: 87680 -

Top ranking of the best smartwatches 2024 - price-quality

Views: 85091 -

Best Complex Vitamins in 2024

Views: 84801 -

The best dye for gray hair - 2024 top ranking

Views: 82406 -

Rating of the best wood paints for interior use in 2024

Views: 77202 -

Ranking of the best action cameras from China in 2024

Views: 75269 -

Rating of the best spinning reels in 2024

Views: 74827 -

The most effective calcium supplements for adults and children in 2024

Views: 72462 -

Top rating of the best in 2024 means for male potency with a description

Views: 68296